Allen-Bradley SLC 5/03, /04, /05 DF1 (Full Duplex) Protocol Setup |

Topic: CM003 |

The following information applies to Allen-Bradley SLC 5/03/ /04, /05 PLC compatible with C-more panels using DF1 Full Duplex Protocol.

The C-more panel is the master by default.

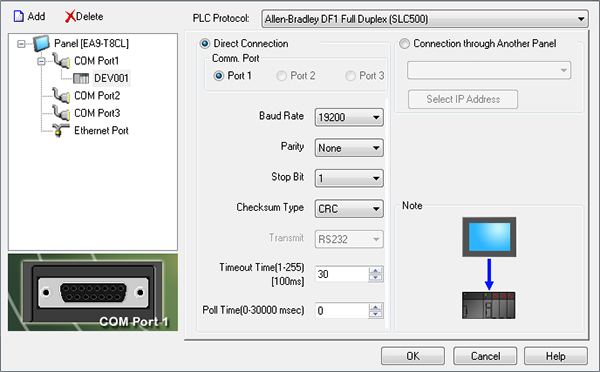

C-more Protocol Manager Settings

- Do one of the following:

- Click the Protocol Manager button on the Home tab

— or — - Click the Protocol Manager button on the Setup tab

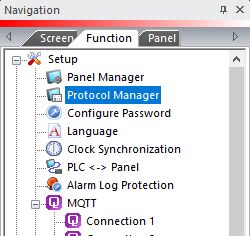

— or — - from the Navigation window, click the Function tab, click Setup and then select Protocol Manager.

- From the Protocol Manager window, click the Device name on the tree to the left.

- The Device Setup window opens.

- From

the PLC Protocol field,

click on the down arrow

and select Allen-Bradley

DF1 Full Duplex (SLC500).

and select Allen-Bradley

DF1 Full Duplex (SLC500).

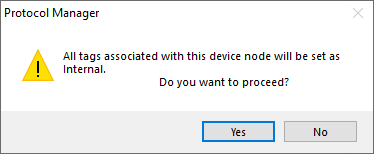

When you select a different PLC Protocol than the one currently in use, the warning Message shown below appears.

- Click Yes to accept.

Setup RSLogix 500

- In RSLogix 500, choose Channel Configuration in the left navigation window.

- From the Channel Configuration window shown below, choose the Channel 0-System tab.

- From this Configuration window, set the following:

- For the Driver field, select DF1 Full Duplex.

- For the Source ID field, leave set at 9.

- For the Control Line field, choose No Handshaking.

- For the following fields, match the C-more Protocol Manager settings:

- Baud Rate

- Parity

- Stop Bits

- Error Detection (Checksum Type)

|

Caution: Record your PLC settings as you change them so that you can reconnect using the same settings later if needed. |

|

|

Note: The Station Address does not matter when using DF1 Full Duplex. |

- Select OK from the Channel Configuration window shown above.

- A Warning window appears.

- Choose Apply from this window.

PLC Address Configuration

- An address must exist in the PLC for every address referenced in the C-more Project. For example, if a Numeric Display in C-more uses address C5:0.ACC, then C5:0.ACC must exist in the PLC Data Files. You can verify addresses in the left side explorer window under Data Files.

- Check to make sure there is a File Number (where 3 is the File Number for B3:0/0 and 7 is the File Number for N7:0).

- Verify is that there are enough elements in the file.

- You can right-click and choose Properties to verify that there is the proper number of elements in the file.

To create a new Data File:

- To create a new Data File:

- Right- click on Data Files and choose New.

|

|

Note: You must be offline to do this. |

- The Create Data File window opens.

- Enter the File Number you wish to use.

- Choose the Data Type.

- Choose the number of elements that you need. For B3:4/0, the 4 is the Element Number.

- This is the same screen that you would use to increase the number of elements of an existing file.

- Select OK and download the changes to the processor.

Connection Through Another Panel

You can configure this protocol for any PLC supported by C-more panels.

You can connect a C-more panel to other C-more panels on your network via an ethernet connection. This type of connection is also known as a Pass Through Connection.

Go to Connection Through Another Panel (Pass-Through) to learn more about Pass Through and using Connection Through Another Panel.

Scenario

No communication between the panel and the PLC.

Most likely cause

Error Detection mismatch (called Checksum Type in the C-more Panel Manager).

Solution

Match the Error Detection.

Scenario

The C-more panel uses the same PLC port you use to connect your PC and RSLogix to the PLC.

Most likely cause

If you change settings for Protocol Manager or RSLogix, RSLogix may be able to reconnect.

Solution

Connect to the PLC through a different port if possible.

Consult your PLC representative for further help on this subject.

|

Caution: Record your PLC settings as you change them so that you can reconnect using the same settings later if needed. |

If your network returns communication errors, test the basic network setup:

Use a new project with :

- Matching PLC Port Settings (check with PLC programming software)

- Matching Protocol Manager settings

- A single Numeric Display object addressed to N7:0

- Transfer the new project.

- Power cycle the PLC.

- Power Cycle the Panel.

If your network continues to return communication errors:

- Power Cycle the Panel.

- Power cycle the PLC.