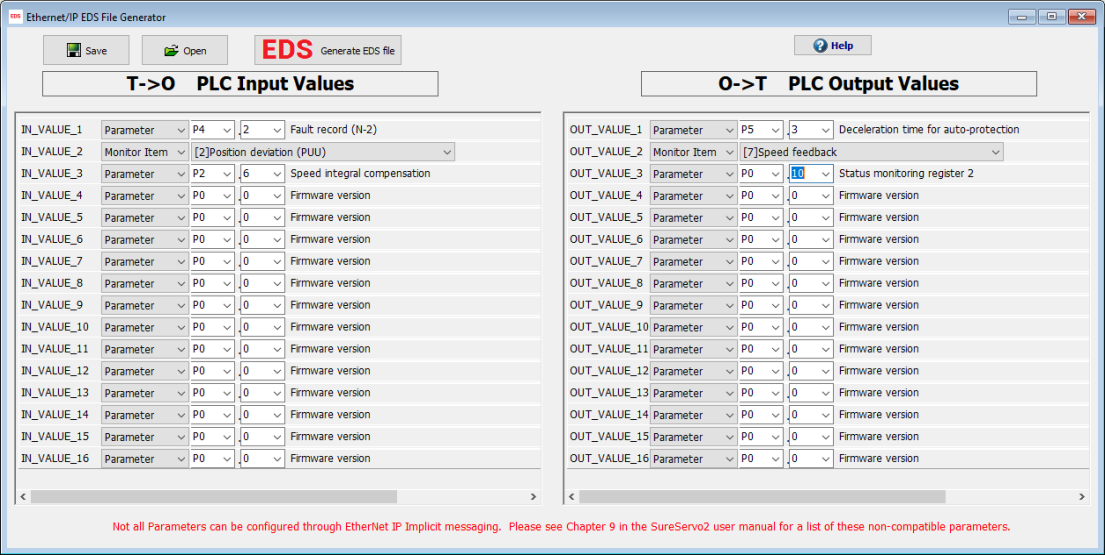

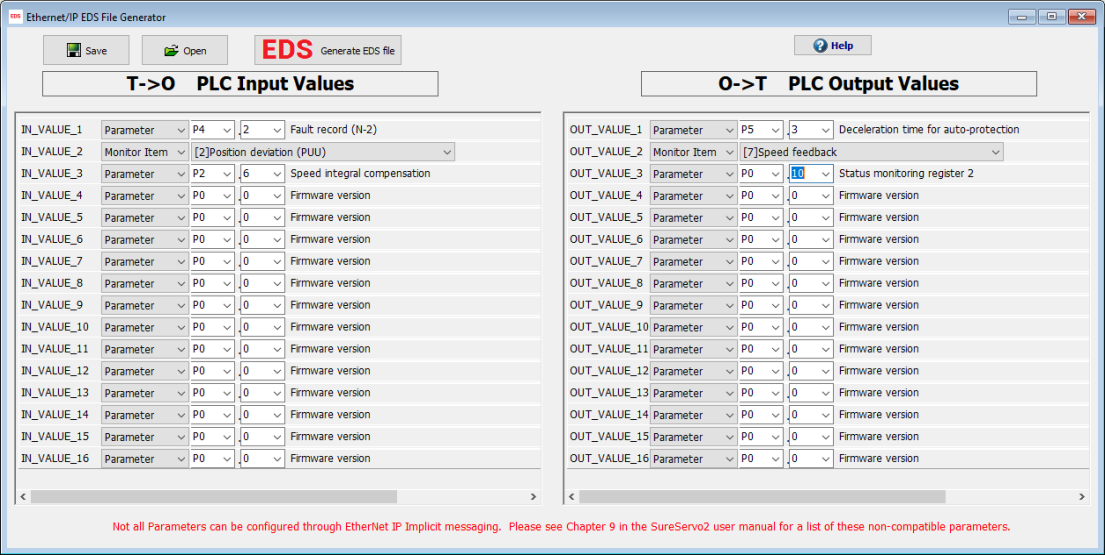

You can use the EtherNet/IP EDS screen to create a customized EDS file for your PLC. This allows you to easily define the Implicit Message between the servo system and the PLC. Each slot for inputs or outputs can be configured for a specific parameter or a chosen monitoring item. You can set any number of inputs and outputs, up to the maximum of 16 inputs and 16 outputs. The settings below can be saved into an .edc file. This window can generate an .eds file that can be imported in your PLC software.

To configure an EDS file, follow the steps below:

1.) Set the desired T->O PLC Input Values using the drop downs.

2.) Set the desired O->T PLC Output Values using the drop downs.

3.) Click the Generate EDS File button.

4.) A Save window will open, navigate to the desired save location and choose a file name, then click Save to save the .eds file.

Note that the EDS settings will not be saved to the drive nor will they be saved in the SureServo2 Pro PAR (parameter) file. This window allows you to save and open the IN_VALUE and OUT_VALUE definitions with an EDC file. Use the Save button to save a copy of the settings to a chosen location. You can use the Open button to open a saved settings file and make changes. Use this to store your EDC file configuration to easily make changes and generate updated EDS files. While SureServo2 Pro can open and save EDC files, the software can't read EDS files (it can only create them).

| Option | Function |

|---|---|

| T->O PLC Input Values | Registers that the PLC wants to read from the servo – like position error, actual speed, actual position, etc. |

| O->T PLC Output Values | Registers that the PLC wants to write to the servo – like set speeds, target positions, etc. |