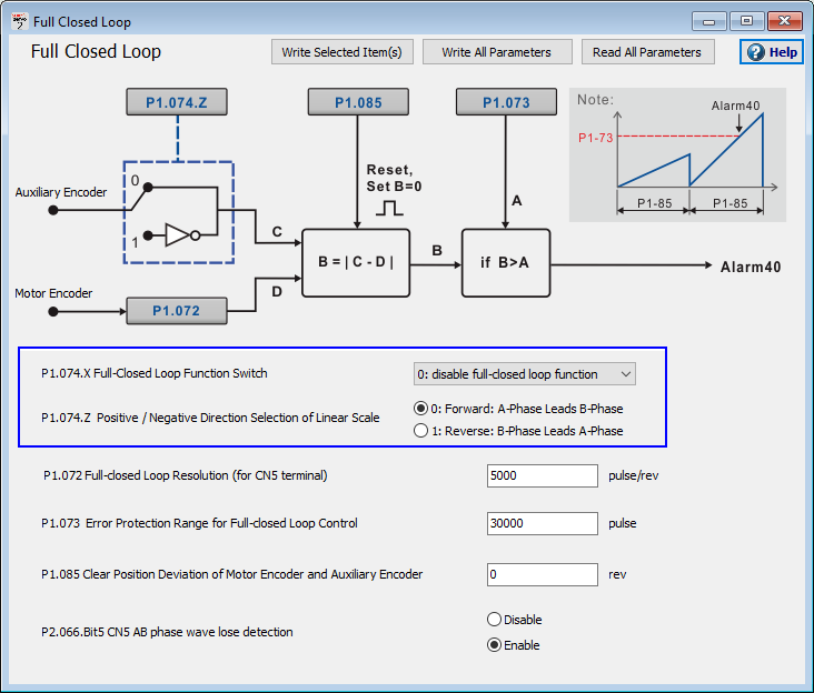

The CN5 connector can connect to an external linear scale or encoder to provide full-closed loop and motor feedback. The Full Closed Loop screen allows you to configure the settings for full closed loop operation when using an external encoder.

You can load the current settings by clicking Read All Parameters.

Parameter data can be adjusted by selecting the appropriate radio button or drop-down menu item. To update multiple parameters, click Write All Parameters to copy the parameter values to the servo. To update just the parameters bounded by the blue box, click Write Selected Item(s).

| Option | Function |

|---|---|

| Full-Closed Loop Function Switch | P1.074.X enables and disables full-closed loop functionality. A value of 0 disables while a value of 1 enables. |

| Positive/Negative Direction Selection of Linear Scale | P1.074.Z sets the positive direction of linear scale feedback. A value of 0 sets positive direction when A phase leads B phase. A value of 1 sets positive direction when B phase leads A phase. |

| Full-close Loop Resolution (for CN5 terminal) | P1.072 sets the A/B pulse corresponding to a full-closed when the motor runs a cycle. The default value is 5000 pulses/rev, possible settings are 200 to 1280000 pulses/rev. |

| Error Protection Range for Full-closed Loop Control | P1.073 sets the acceptable deviation between the linear scale A/B Counter and the encoder feedback position. If the value in P1.073 is exceeded, AL040 (excessive deviation of full closed-loop position control) occurs. The default value is 30000 pulses, possible settings are 1 to 231-1 pulses. |

| Clear Position Deviation of Motor Encoder and Auxiliary Encoder | P1.085 sets the number of revolutions before P1.073 position deviation will fault the system. Use this to eliminate nuisance faults. |

| CN5 AB Phase Wave Lose Detection | P2.066.Bit5 enables or disables disconnection detection for the linear encoder. Enable with 1, disable with 0. If enabled, AL041 will be triggered if the linear encoder is disconnected. |