XGB EtherCAT CAM Data Creation and Using XPM_CAM or XPM_CAMO

XEM CPU supports up to 8 different CAM blocks using various CAM profiles. The CAM blocks are created in XG-PM software. The XPM_CAM and XPM_CAMO function blocks are used to execute any created CAM blocks.

-

A User CAM operation is available and is accessed as CAM block number 9.

-

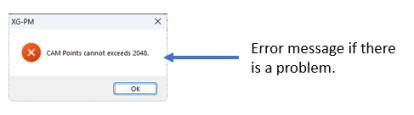

A maximum of 2048 points can be generated per CAM block. An error will appear if a block will have too many points.

-

A CAM block supports one master axis and one sub-axis.

-

XPM_ECON and XPM_SVON must be executed before any motion.

| Function Block | Description in XG5000 | Function |

|---|---|---|

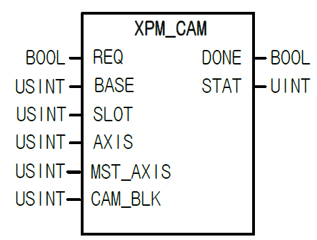

| XPM_CAM | CAM run | Execute a predefined CAM block with the slave axis according to the movement of the master axis. |

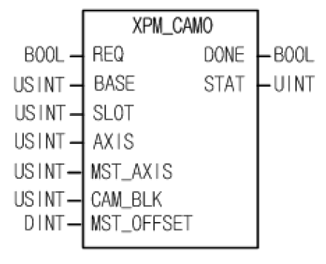

| XPM_CAMO | CAM run with master offset | Execute a predefined CAM block with the slave axis after the master axis moved the distance defined as the offset. |

XPM_CAM is used for executing a CAM block of a sub-axis. MST_AXIS should have the same unit configuration as the CAM block. The axis that uses the XPM_CAM function block is considered the sub-axis.

| Element Name | Element Type | Description |

|---|---|---|

| REQ | Input | Edge detected request to execute the function block. |

| BASE | Input | Base number of the motion controller. Set to 0. |

| SLOT | Input | Slot number of the motion controller. Set to the slot number of the XBF-PN04B or XBF-PN08B module. |

| AXIS | Input | Axis number to control. XBF-PN04B:1~4, XBF-PN08B:1~8 |

| MST_AXIS | Input | Master axis number. XBF-PN04B:1~4, XBF-PN08B:1~8 and must not be the axis executing the XPM_CAM. |

| CAM_BLK | Input | CAM block number to execute. XBF-PN04B:1~4, XBF-PN08B:1~8. 9 allows the execution of a USER CAM Operation. |

| DONE | Output | Status that function block is done. |

| STAT | Output | Current status of the function block. Non-zero numbers will be an error or warning. |

XPM_CAMO is used for executing a CAM block of a sub-axis with an added master offset position. MST_AXIS should have the same unit configuration as the CAM block. The axis that uses the XPM_CAMO function block is considered the sub-axis.

| Element Name | Element Type | Description |

|---|---|---|

| REQ | Input | Edge detected request to execute the function block. |

| BASE | Input | Base number of the motion controller.Set to 0. |

| SLOT | Input | Slot number of the motion controller. Set to the slot number of the XBF-PN04B or XBF-PN08B module. |

| AXIS | Input | Axis number to control. XBF-PN04B:1~4, XBF-PN08B:1~8 |

| MST_AXIS | Input | Master axis number. XBF-PN04B:1~4, XBF-PN08B:1~8 and must not be the axis executing the XPM_CAMO. |

| CAM_BLK | Input | CAM block number to execute. XBF-PN04B:1~4, XBF-PN08B:1~8. 9 allows the execution of a USER CAM Operation. |

| MST_OFFSET | Input | Set the master’s offset position. |

| DONE | Output | Status that function block is done. |

| STAT | Output | Current status of the function block.Non-zero numbers will be an error or warning. |

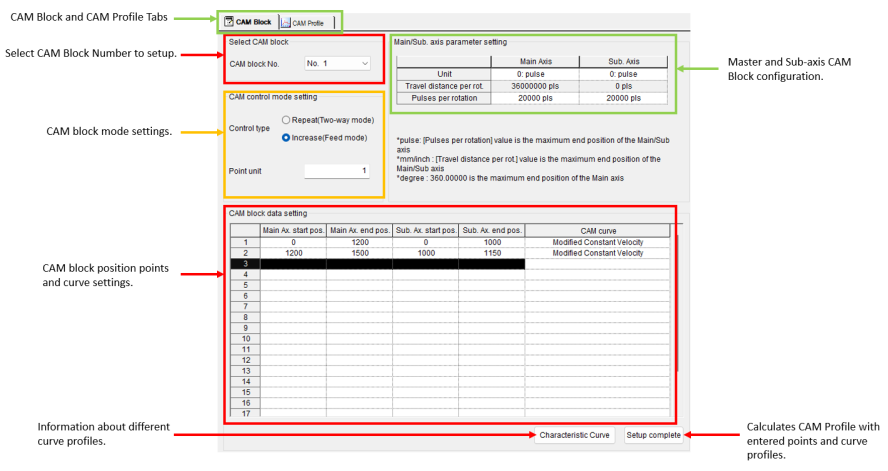

The XG-PM software is used to create CAM blocks 1 through 8.

| Step | Action |

|---|---|

| 1 |

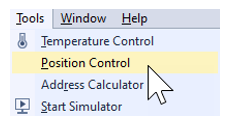

Open the XG5000 project for the application. Go to Tools menu èPosition Control to open XG-PM software.

|

| 2 |

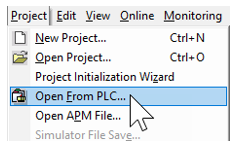

Open the XG-PM project or Connect to PLC and select ProjectèOpen from PLC.

|

| 3 |

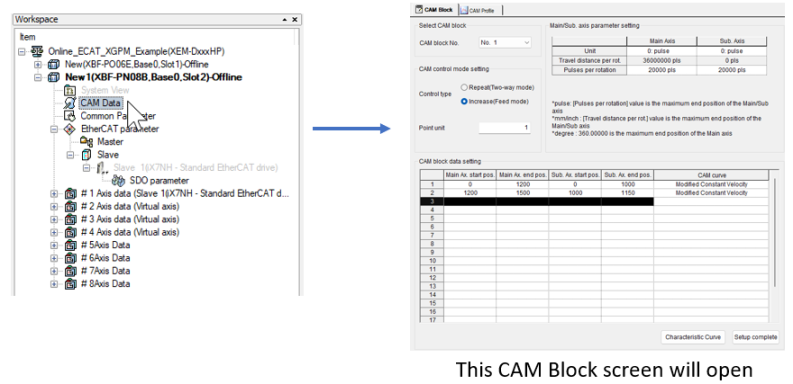

Open the CAM Data file in the workspace.

|

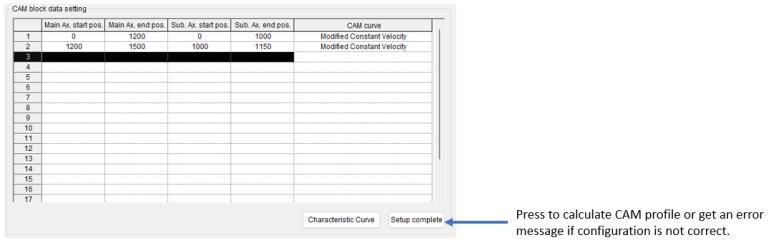

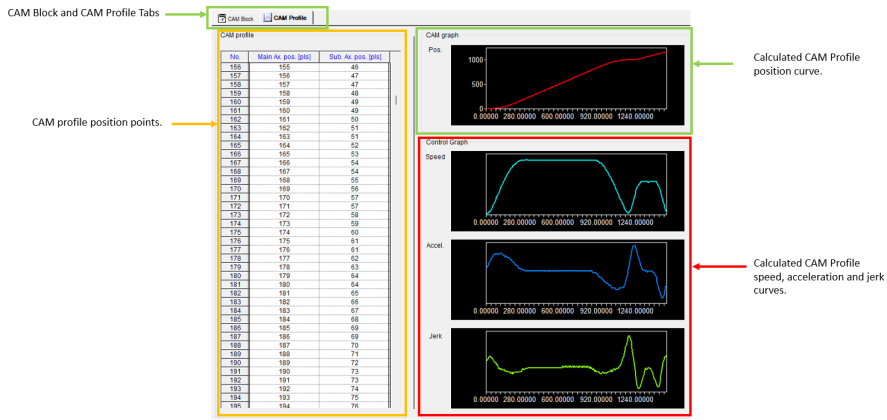

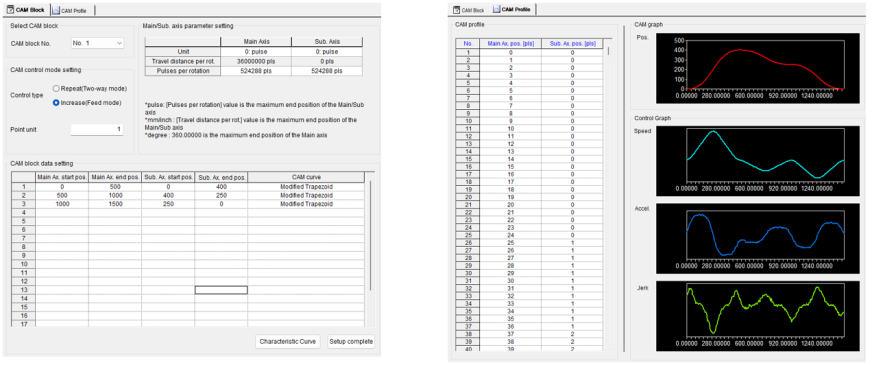

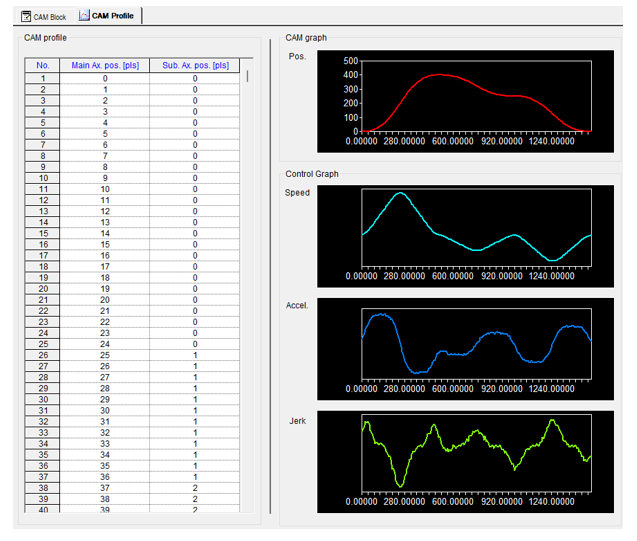

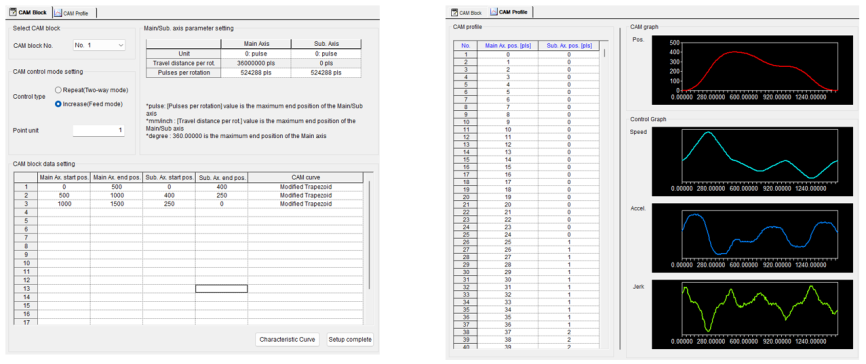

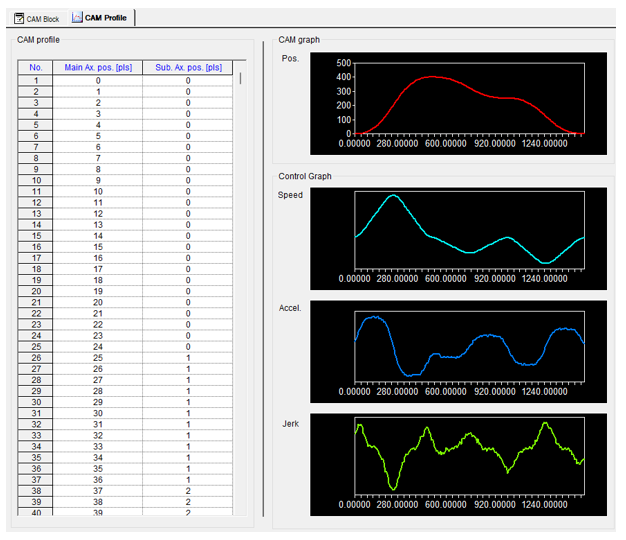

CAM Block Screen Layout

CAM Profile Screen Layout

| Step | Action |

|---|---|

| 1 |

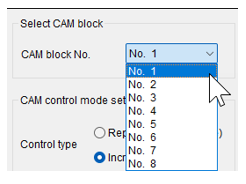

Choose a CAM block number to configure.

|

| 2 |

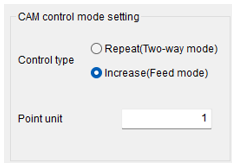

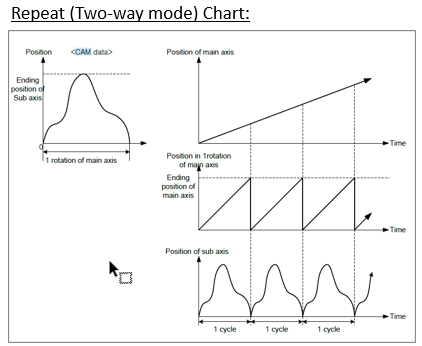

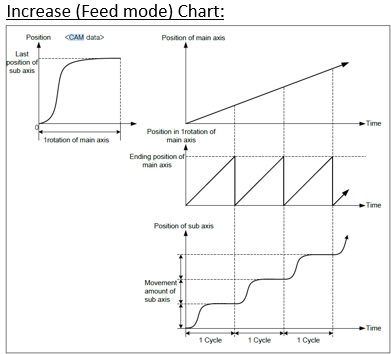

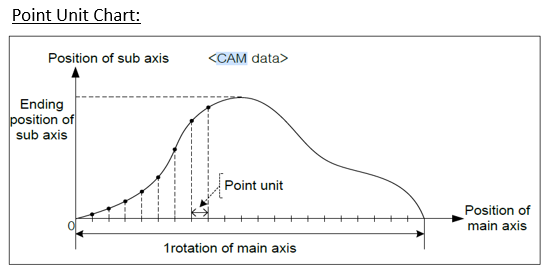

Configure the CAM block mode settings.

|

| 3 |

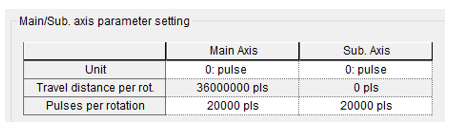

Configure Main and Sub axis parameters.

|

| 4 |

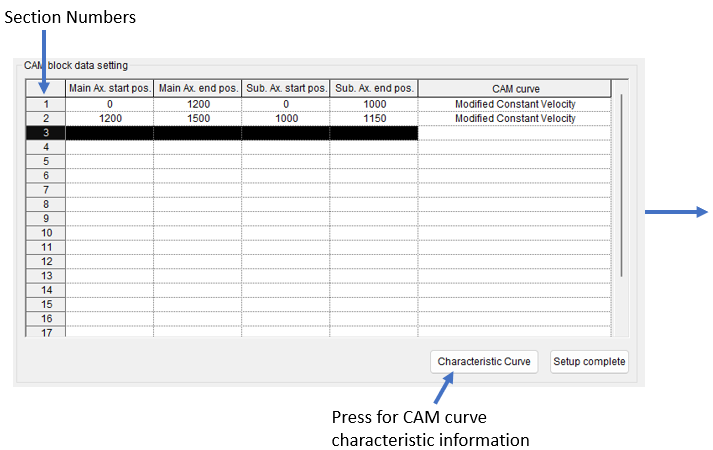

Enter CAM block data. Make sure block data matches restrictions of CAM block configuration.

|

| 5 |

Press Setup complete button to calculate the CAM Profile.

|

| 6 |

Save the project. Connect to the CPU and write the project to the CPU. Note: If connecting XG5000 and XG-PM at the same time, make sure to connect XG5000 first. XG5000 will give error messages if it is connected last. |

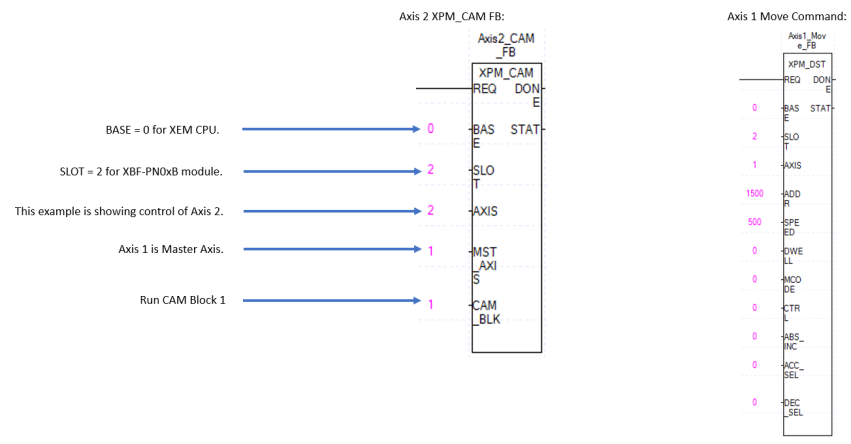

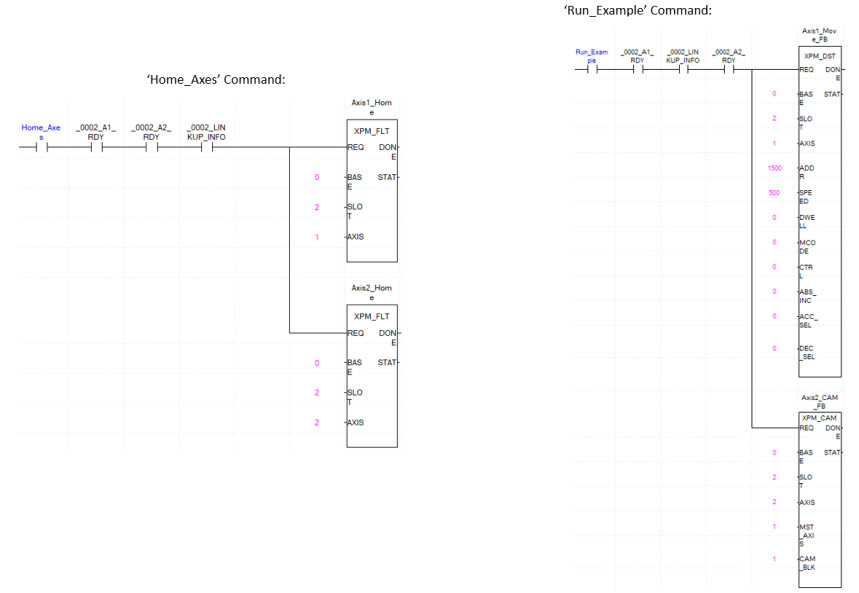

This example is in scan program LP636_XPM_CAM_Example in OnlineHelp_ECAT_Example. In this example Axis 1 is the master axis and Axis 2 is the sub-axis.

-

When the ‘Run_Example’ variable is true, Axis 1 will do an absolute move to position 1500 pulses at 500 pulses/sec and Axis2 will execute an XPM_CAM function block.

-

Axis 2’s XPM_CAM is setup to execute CAM block 1.

-

Home Axes before setting ‘Run_Example ‘ to true.

-

CAM Block 1 is in XG_PM program LP533_CAMExample_XGPM.xpj

CAM Block 1

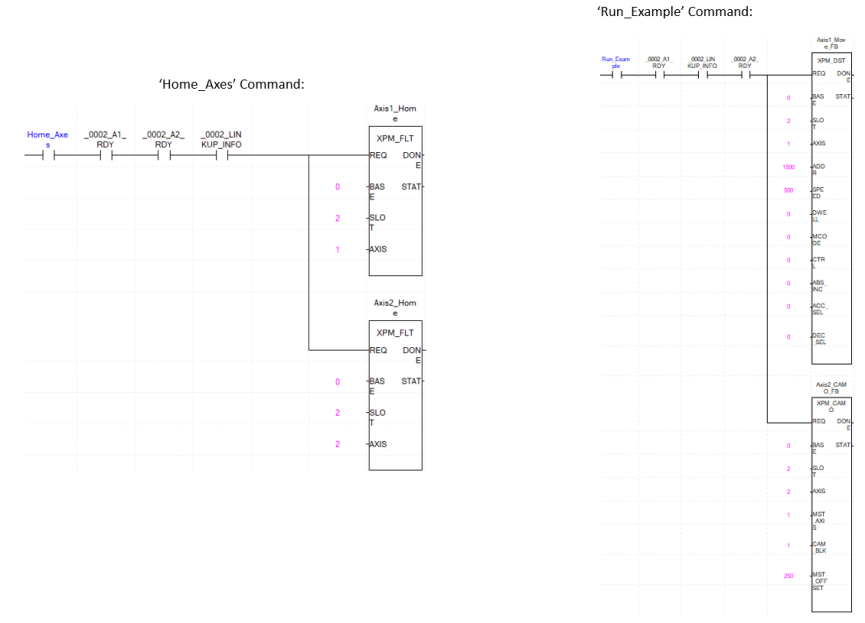

XPM_CAM LD Code

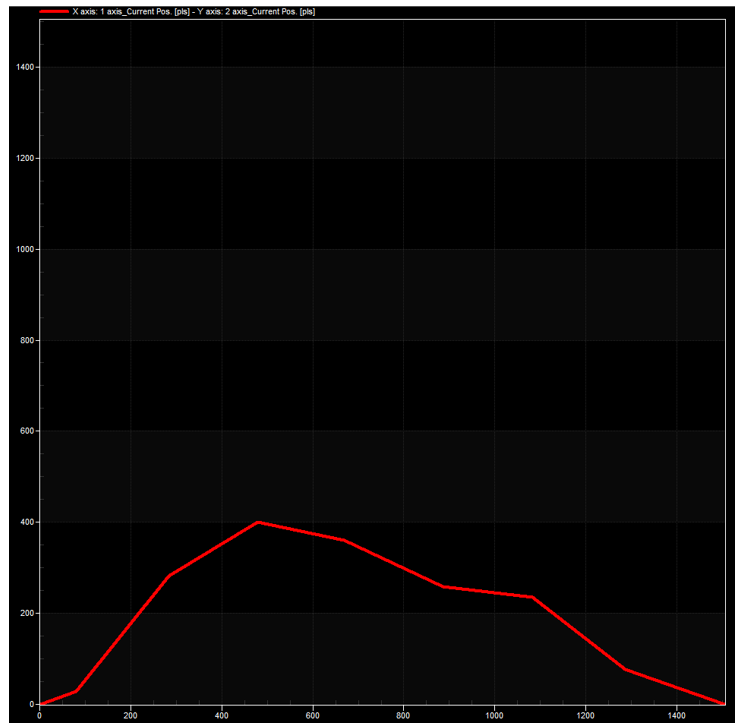

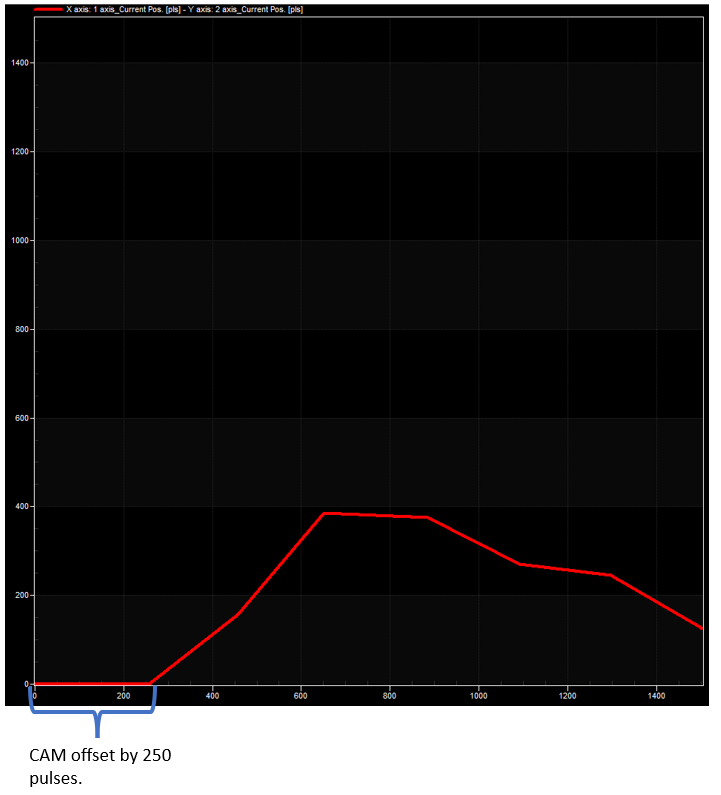

XPM_CAM XG-PM Trend Compared to CAM Profile

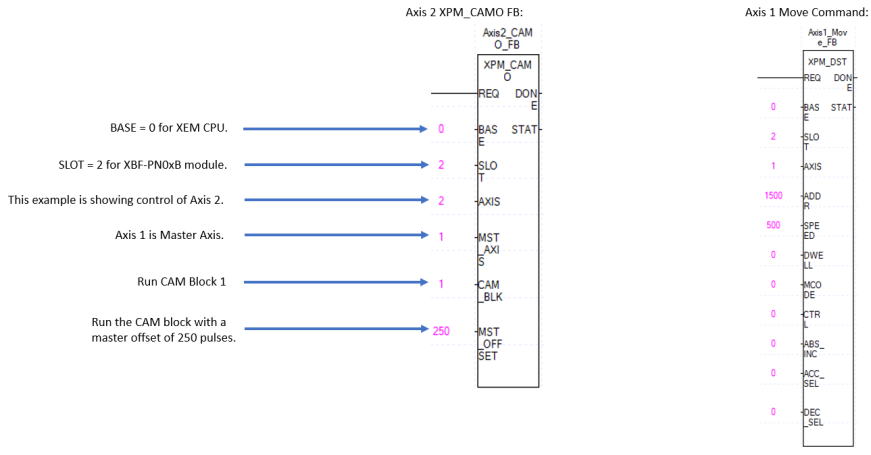

This example is in scan program LP636_XPM_CAMO_Example in OnlineHelp_ECAT_Example. In this example Axis 1 is the master axis and Axis 2 is the sub-axis.

-

When the ‘Run_Example’ variable is true, Axis 1 will do an absolute move to position 1500 pulses at 500 pulses/sec and Axis2 will execute an XPM_CAMO function block.

-

Axis 2’s XPM_CAMO is setup to execute CAM block 1.

-

Home Axes before setting ‘Run_Example ‘ to true.

-

CAM Block 1 is in XG_PM program LP533_CAMExample_XGPM.xpj

CAM Block 1

XPM_CAMO LD Code

XPM_CAMO XG-PM Trend Compared to CAM Profile

LP636