EtherCAT Servo Error Read with XPM_SVERD and Reset with XPM_SRST

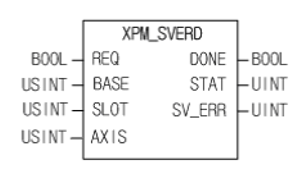

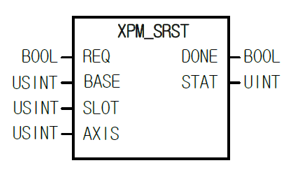

The XPM_SVERD function block is used to read servo error information from an axis. The XPM_SRST is used to reset an error on a servo axis.

-

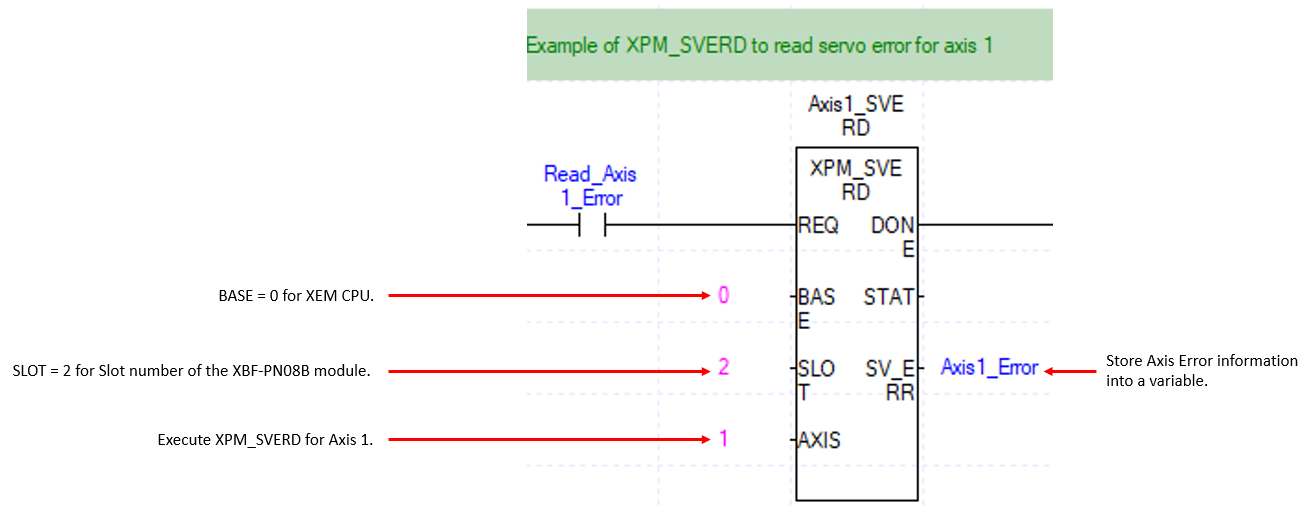

The following examples can be found in OnlineHelp_ECAT_Example.

-

XPM_ECON needs to be executed first so EtherCAT servo drives are connected to receive commands.

-

The XPM_SVERD and XPM_SRST function blocks only work with EtherCAT servo drives.

| Element Name | Element Type | Description |

|---|---|---|

| REQ | Input | Edge detected request to execute the function block |

| BASE | Input | Base number of the motion controller. Set 0 to the Base number. |

| SLOT | Input | Slot number of the motion controller. Set to the slot number of the XBF-PN04B or XBF-PN08B module. |

| Axis | Input | Axis to read error information from. |

| DONE | Output | Status that function block is done. |

| STAT | Output | Current status of the function block. Non-zero numbers will be an error or warning. |

| SV_ERR | Output | Servo error information. |

| Element Name | Element Type | Description |

|---|---|---|

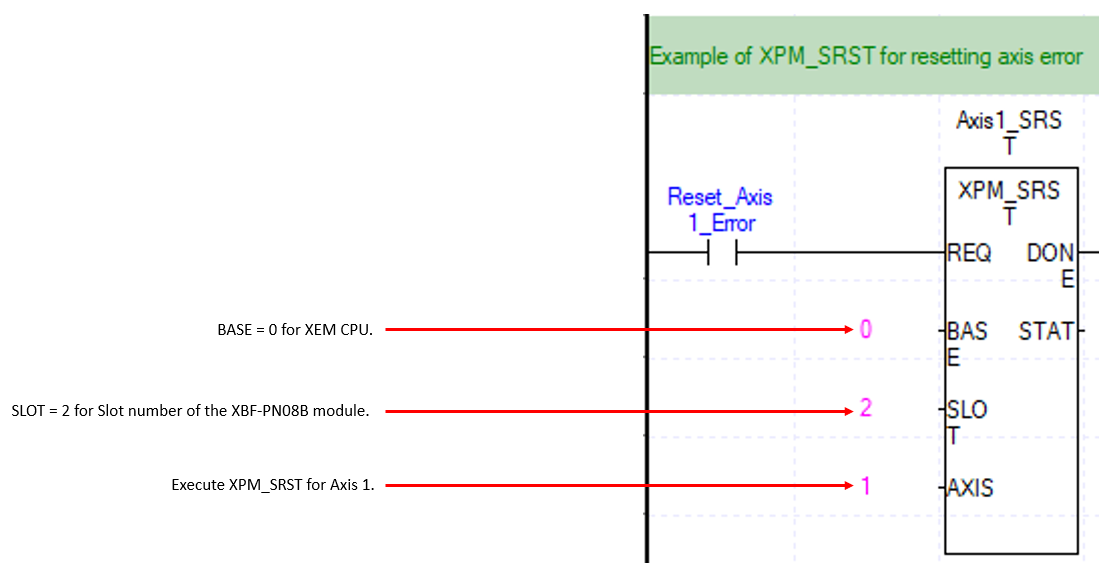

| REQ | Input | Edge detected request to execute the function block |

| BASE | Input | Base number of the motion controller. Set 0 to the Base number. |

| SLOT | Input | Slot number of the motion controller. Set to the slot number of the XBF-PN04B or XBF-PN08B module. |

| Axis | Input | Axis to command with function block. XBF-PN04B=1-4, XBF-PN08B=1-8. |

| DONE | Output | Status that function block is done. |

| STAT | Output | Current status of the function block. Non-zero numbers will be an error or warning. |

Note: If the cause for the drive error is not corrected, then the error may not be cleared.

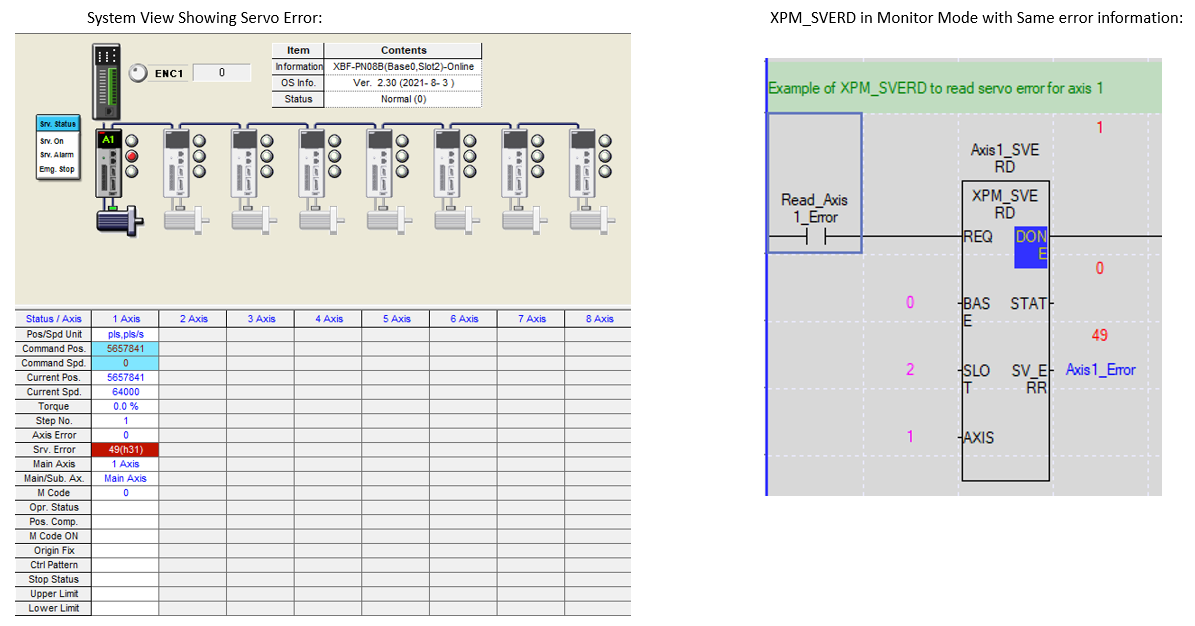

XPM_SVERD Example Results

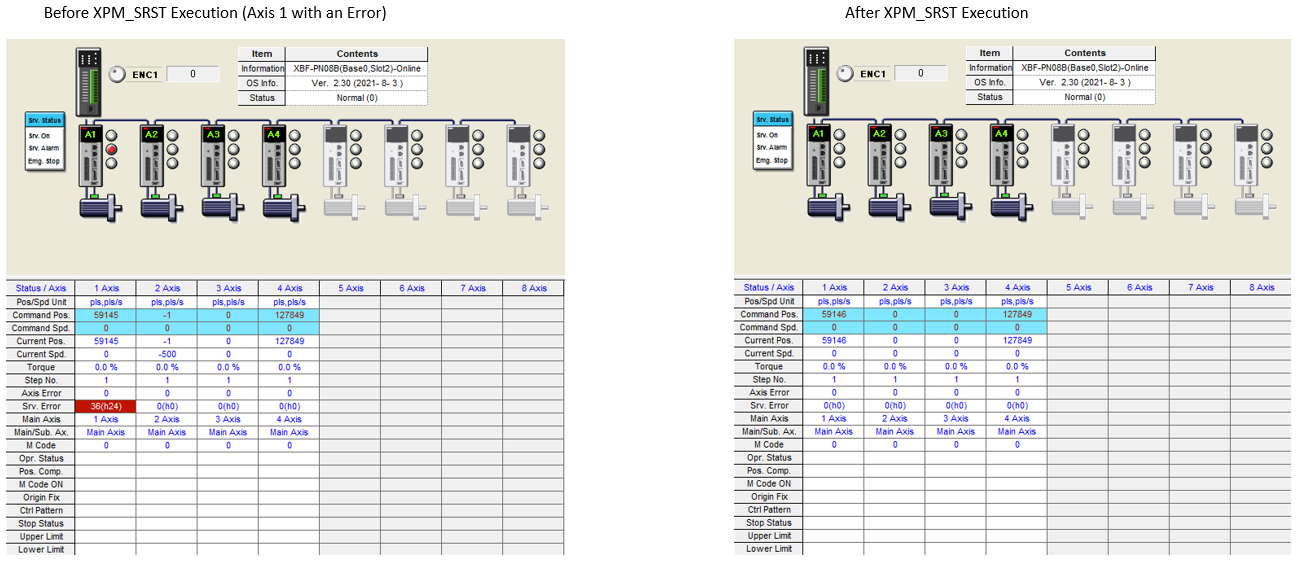

XG-PM System View after executing XPM_SRST

Note: Power cycling an EtherCAT servo drive will disconnect the EtherCAT network. XPM_ECON will need to be used to reconnect it.

| Alarm | Error Description | XPM_SRST Can Reset |

Software Reset or Power Cycle Needed |

|---|---|---|---|

| AL-10 | IPM Overcurrent (H/W) | ✓ | |

| AL-14 | Overcurrent (S/W) | ✓ | |

| AL-16 | Current limit exceeded | ✓ | |

| AL-11 | IPM temperature Overheat | ✓ | |

| AL-15 | Current offset abnormality | ✓ | |

| AL-21 | Continuous Overload | ✓ | |

| AL-22 | Drive Temperature 1 | ✓ | |

| AL-23 | Regeneration overload | ✓ | |

| AL-24 | Motor cable disconnected | ✓ | |

| AL-25 | Drive Temperature 2 | ✓ | |

| AL-26 | Encoder Temperature | ✓ | |

| AL-28 | DC cooling fan abnormality | ✓ | |

| AL-29 | Regeneration brake fault | ✓ | |

| AL-30 | Encoder communication error | ✓ | |

| AL-31 | Encoder cable open | ✓ | |

| AL-32 | Encoder data error | ✓ | |

| AL-33 | Motor ID setting error | ✓ | |

| AL-34 | Encoder Z-phase loss | ✓ | |

| AL-35 | low voltage encoder battery | ✓ | |

| AL-36 | Encoder Sine wave amplitude error | ✓ | |

| AL-37 | Encoder Sine wave frequency error | ✓ | |

| AL-38 | Encoder setting error | ✓ | |

| AL-3B | Encoder position error | ✓ | |

| AL-40 | Under voltage | ✓ | |

| AL-41 | Over voltage | ✓ | |

| AL-42 | Main power fail | ✓ | |

| AL-43 | Control power fail | ✓ | |

| AL-50 | Over speed limit | ✓ | |

| AL-51 | Excessive Position error | ✓ | |

| AL-53 | Excessive SPD deviation | ✓ | |

| AL-56 | Excessive Position Control | ✓ | |

| AL-57 | Excessive pulse output speed | ✓ | |

| AL-63 | Parameter checksum | ✓ | |

| AL-71 | Factory setting abnormality | ✓ |

LP608