CAM Data Creation and Using XPM_CAM or XPM_CAMO

XEM CPU supports up to 8 different CAM blocks using various CAM profiles.

-

The CAM blocks are created in XG-PM software.

-

The XPM_CAM and XPM_CAMO function blocks are used to execute any created CAM blocks.

-

A User CAM operation is available and is accessed as CAM block number 9.

-

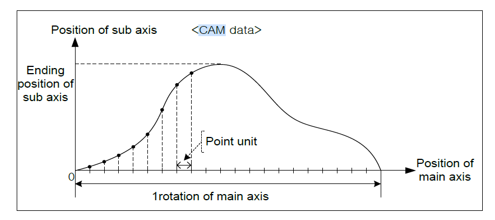

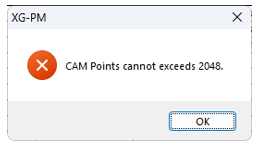

A maximum of 2048 points can be generated per CAM block. An error will appear if a block will have too many points.

-

A CAM block supports one master axis and one sub-axis.

| Function Block | Description in XG5000 | Function |

|---|---|---|

| XPM_CAM | CAM run | Execute a predefined CAM block with the slave axis according to the movement of the master axis. |

| XPM_CAMO | CAM run with master offset | Execute a predefined CAM block with the slave axis after the master axis moved the distance defined as the offset. |

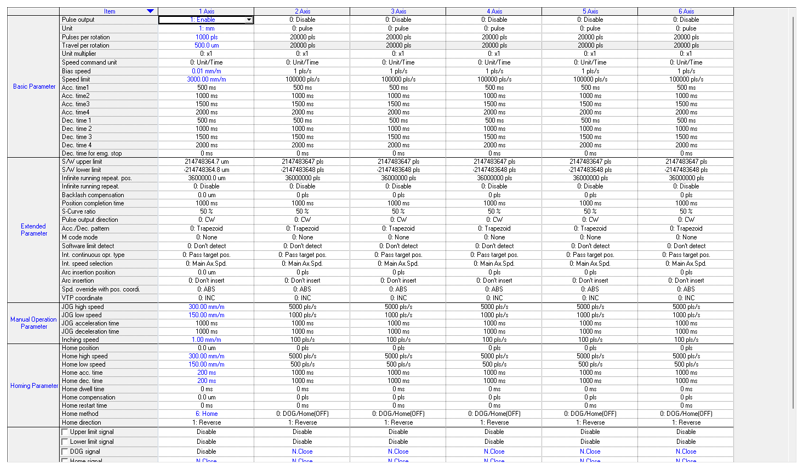

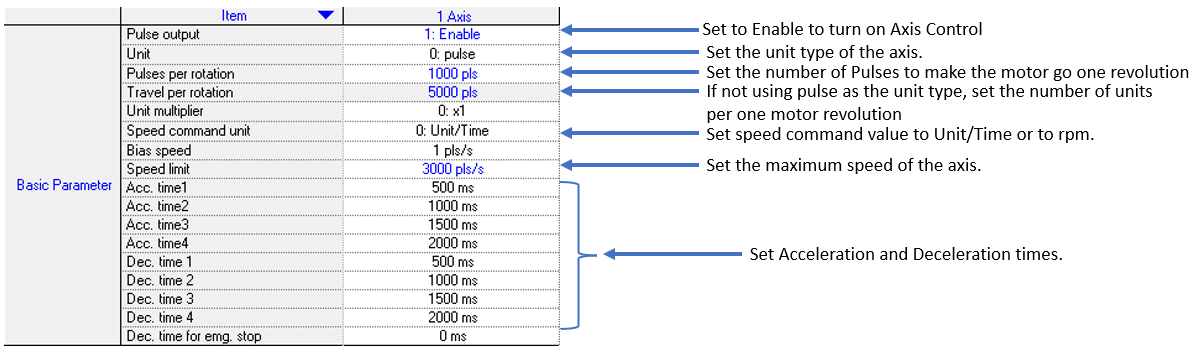

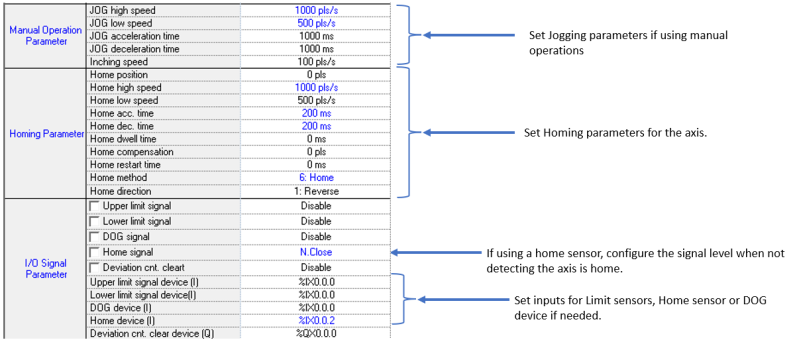

These examples show control of Axis 1 by an XEM-DN32HP CPU.

-

Axis 1 is a LS Electric L7CA004U-AD connected to a linear actuator with a 5 mm pitch.

-

The L7C servo drive is configured to have 1000 pulses be one revolution of the motor.

| Step | Action |

|---|---|

| 1 |

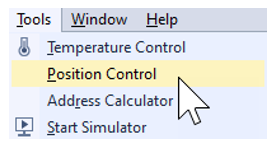

Open the XG5000 project for the application. Go to Tools menu èPosition Control to open XG-PM software.

|

| 2 |

Open the XG-PM project or connect to PLC and select ProjectèOpen from PLC.

|

| 3 |

Open the Parameter file in the Workspace for the axis that is being configured. This example shows Axis #1.

This parameter screen will open:

|

| 4 |

Configure the parameters of the Axis. This example shows Axis 1.

|

| 5 |

Save the project. Connect to the CPU and write the project to the CPU. Note: If connecting XG5000 and XG-PM at the same time, make sure to connect XG5000 first. XG5000 will give error messages if it is connected last. |

The XG-PM software is used to create CAM blocks 1 - 8.

| Step | Action |

|---|---|

| 1 |

Open the XG5000 project for the application. Go to Tools menu è Position Control to open XG-PM software.

|

| 2 |

Open the XG-PM project or connect to PLC and select Project è Open from PLC.

|

| 3 |

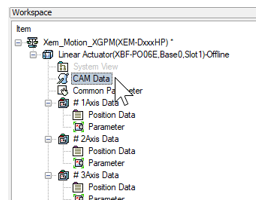

Open the CAM Data file in the Workspace.

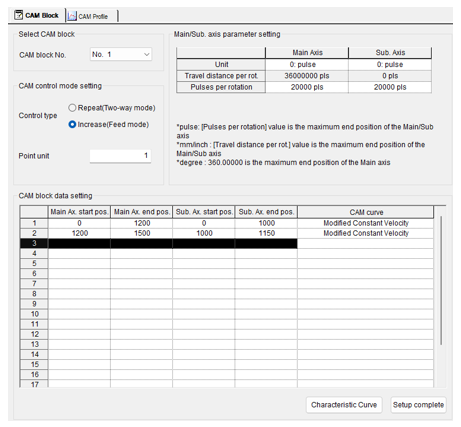

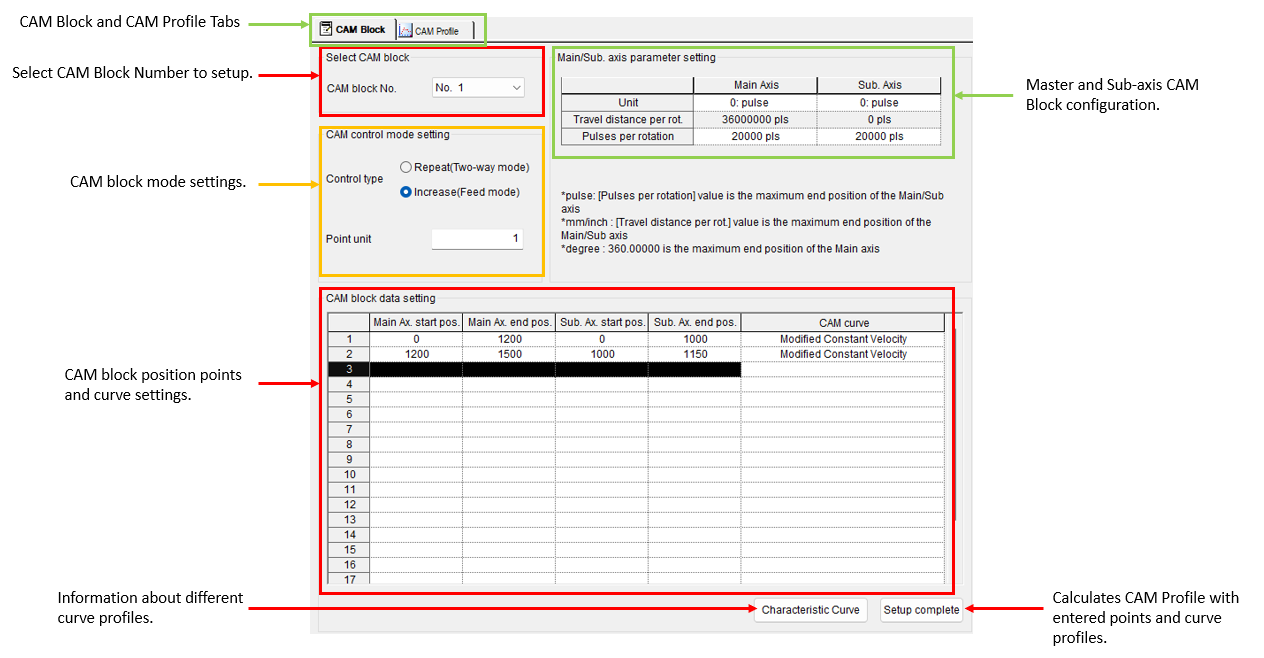

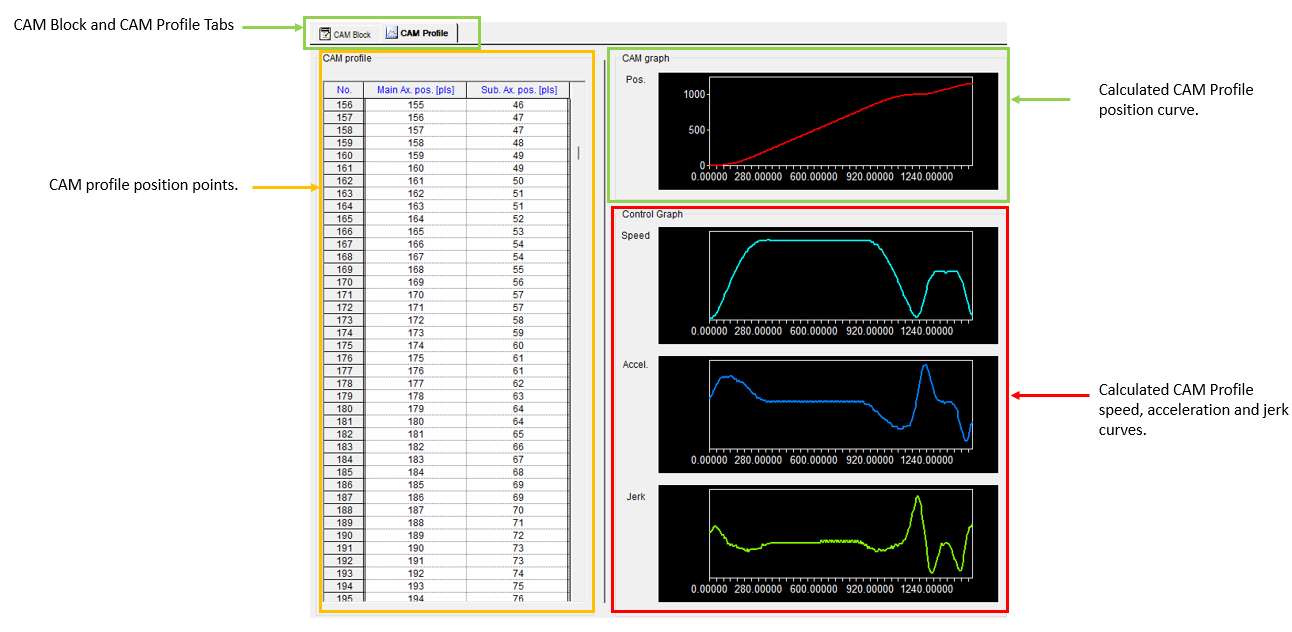

The CAM Block screen will open:

|

| Step | Action |

|---|---|

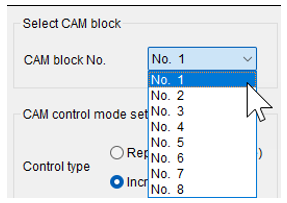

| 1 |

Choose a CAM block number to configure.

|

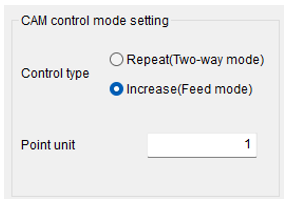

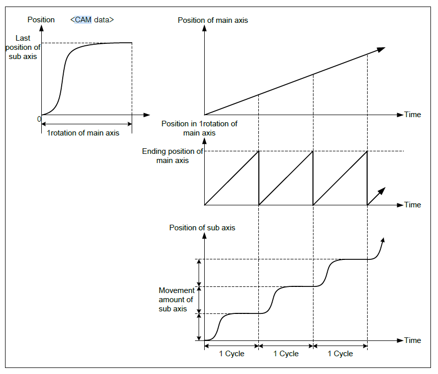

| 2 |

Configure the CAM block mode settings.

|

| 3 |

Configure Main and Sub axis parameters.

|

| 4 |

Enter CAM block data. Make sure block data matches restrictions of CAM block configuration.

|

| 5 |

Press Setup complete button to calculate the CAM Profile.

Goes to CAM Profile screen when successful.

Error message if there is a problem

|

| 6 |

Save the project. Connect to the CPU and write the project to the CPU. Note: If connecting XG5000 and XG-PM at the same time, make sure to connect XG5000 first. XG5000 will give error messages if it is connected last. |

Using XPM_CAM and XPM_CAMO

See the topics below for examples using XPM_CAM and XPM_CAMO.

LP533